*lWOODWORK SOLUTION 💯

1b)

i. Saw

ii. Tape rules

iii. Punch

iv. G-clamp

v. Wrenches

3ai)

A panel saw is designed to cut panel material to a given size and uses a specific panel blade with more teeth and a finer cut. Horizontal Panel saws generally have a sliding table to help with feeding larger boards. There are vertical “Wall saws” and high production “Beam saws”

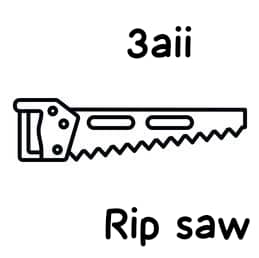

3aii)

A rip saw is primarily used to rip down solid timber planks to a given width with a specific timber rip blade. There are also power fed “Resaw bandsaws” for larger material and higher production.

4ai)

Stiffness strength is a material’s ability to return to its original form after being subjected to a force.

4aii)

Toughness is the ability to measure the amount of force a material can absorb without fractioning.

4aiii)

tensile strength is the maximum stress that a material can withstand while being stretched or pulled before breaking.

5a) EMC stands for Equilibrium Moisture Content, which is the moisture content that wood can reach when it has come to a balance with the surrounding environment. This applies to woodwork because maintaining the EMC is important to ensure that the wood is stable and does not warp or crack due to changes in moisture content. Achieving this balance requires controlling the environment in which the wood is stored or used, such as by controlling temperature, humidity, and ventilation.

5b) The initial weight of the sample was 63g, and after being seasoned, it weighed 56g. This means that 7g of moisture was lost during seasoning. To find the required percentage moisture, we need to calculate the percentage of moisture in the original sample.

Percentage moisture = (moisture content / weight of sample) x 100

Moisture content = initial weight – seasoned weight = 63g – 56g = 7g

Percentage moisture = (7g / 63g) x 100 = 11.11%

Therefore, the required percentage moisture for this sample is 11.11%.

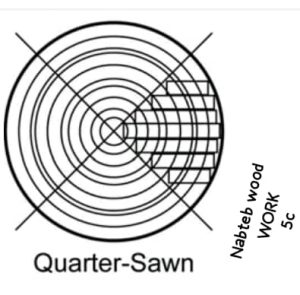

(5c)

*(CHECK THE DIAGRAM ABOVE)*

*-Advantages of Quarter Sawing Method-*

(i) Quarter sawn timber is more dimensionally stable and less prone to warping, twisting and cupping than other sawn timber.

(ii) Quarter sawing produces attractive straight grain patterns which are highly sought after in furniture and joinery manufacturing.

(iii) The quarter sawing method also produces wood that is more wear-resistant and durable than other methods.

(iv) The straight grain pattern also results in better resistance to atmospheric changes such as humidity and temperature variations.

(iv) It produces high yield with very little waste as compared to other methods of sawing timber.

*-Disadvantages of Quarter Sawing Method-*

(i)The process of quarter sawing is expensive due to the amount of labour and time required.

(ii) The process of quarter sawing produces a large quantity of waste as compared to other methods of sawing timber.

(iii) Limited Availability – Due to its popularity and high demand, quarter sawn timber is sometimes difficult to acquire and may be more expensive.

(iv) The cutting process is more difficult because of the need for maintaining a straight grain pattern. This can lead to more saw blade wear and tear, and can increase the amount of sawdust produced.

(v) The process of quarter sawing involves more time due to the need for precise cuts and the need to maintain a straight-grain pattern, which can increase production time.

Leave a Reply