NABTEB 2024 MECHANICAL ENGINEERING CRAFT PRACTICE ANSWERS | OBJ AND ESSAYS

MECHANICAL ENGINEERING

01-10: CCCDADBBDD

11-20: CCDABCAABA

21-30: DDACCACBBB

31-40: BACDBBCABC

COMPLETED

“`ANSWER FIVE(5) QUESTIONS ONLY“`

(1a)

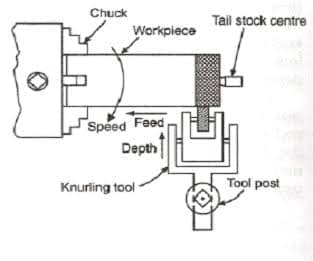

Special purpose lathe machine is designed for a specific operation or type of workpiece (e.g., precision turning, grinding, or drilling) whereas General purpose lathe machine is versatile and can perform various operations (e.g., turning, facing, drilling, and knurling) on different workpieces

(1b)

(i) Reduces heat generation and tool wear

(ii) Improves surface finish and accuracy

(iii) Enhances cutting tool life

(iv) Helps remove chips and debris

(1c)

==========================

(2a)

(i) Maintains accuracy and straightness

(ii) Prevents wandering or vibration

(iii) Reduces heat buildup and tool wear

(iv) Improves surface finish

(2b)

Sensitive feed refers to a feature or setting in various platforms or applications, especially in social media or content aggregation services

(2c)

==========================

Read more;

NABTEB 2024 Introduction To Building Construction Answers

NABTEB Literature 2024 Obj & Prose Answers

NABTEB Electrical Installation Obj & Essay 2024

NABTEB 2024 Building/Engineering Drawing Objectives

(3ai)

(Draw the diagram)

[img]https://i.ibb.co/6sj1rrh/Ball-peen.jpg[/img]

Ball Pein Hammer: A ball pein hammer has a flat face on one side and a rounded pein on the other. It is typically used for shaping metal, setting rivets, and striking metal tools.

(3aii)

(Draw the diagram)

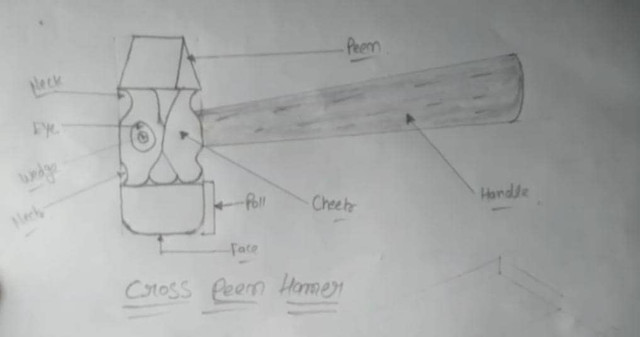

Cross Pein Hammer: A cross pein hammer has a flat face on one side and a wedge-shaped pein on the other at a right angle. It is commonly used for metalworking tasks like bending, shaping, and riveting.

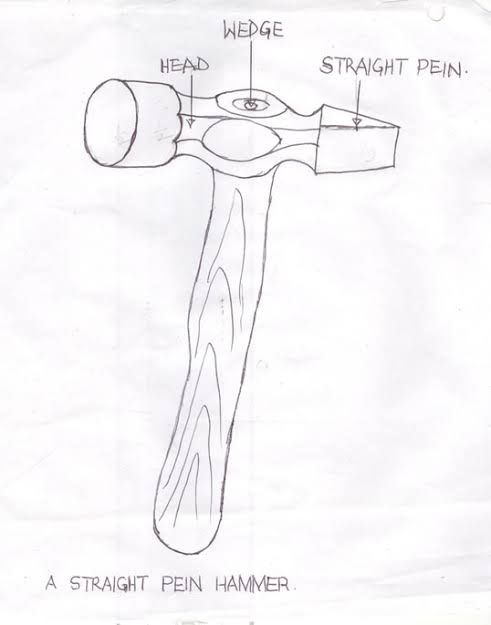

(3aiii)

(Draw the diagram)

Straight Hammer: Straight hammers have a flat face for driving nails and a straight claw on the opposite side for pulling nails out of wood or other materials. They are versatile and widely used for various carpentry and construction tasks.

(3b)

(i) Filing parallel slots:

Half-round file (for curved slots) or Square file (for square slots)

(ii) Filing flat surfaces:

Flat file (single-cut or double-cut)

(iii) Filing a rectangular hole:

Warding file (for precise, rectangular openings)

==========================

(5a)

(Draw the diagram)

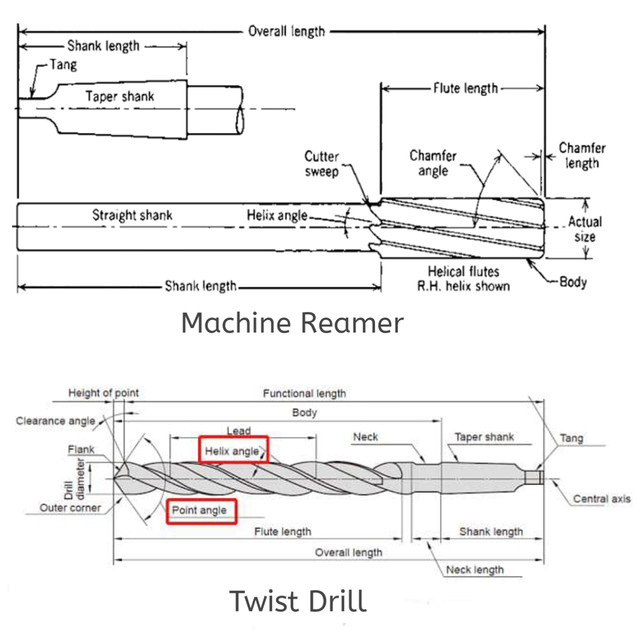

(i) Reamers are used for finishing holes, while twist drills are used for creating new holes.

(ii) Reamers have a high degree of accuracy in size and finish, while twist drills may have slightly less precise results.

(iii) Reamers have a limited cutting length, while twist drills can drill deeper holes.

(iv) Reamers have a lead-in taper for easier alignment, while twist drills start drilling directly.

(v) Reamers generally have fewer flutes than twist drills for better chip evacuation.

(vi) Reamers require pre-drilled holes before use, while twist drills can start directly on the material surface.

(5b)

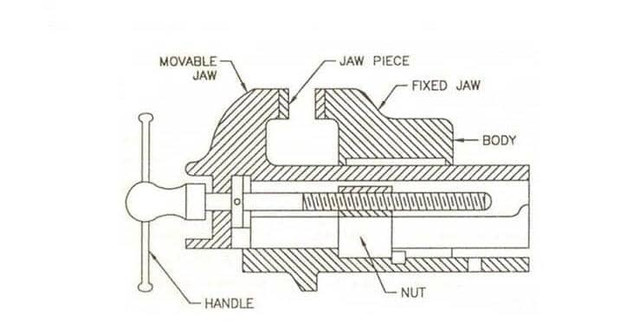

(i) Bench vice:

-Holding workpieces securely in place

-Clamping materials for drilling, sawing, or filing

-Supporting work during machining operations

(ii) Centre punch:

-Marking center points for drilling or machining

-Creating a starting point for drilling

-Making a small indentation to guide a drill bit

(iii) Bevel protractor:

-Measuring and marking angles (e.g., 45° or 60°)

-Checking and setting angles on workpieces or tools

-Transferring angles from one surface to another

==========================

(6a)

(i) Wear and tear on the cutting edges

(ii) Overheating due to excessive friction or speed

(iii) Poor drill bit quality or incorrect drill bit selection

(6bi)

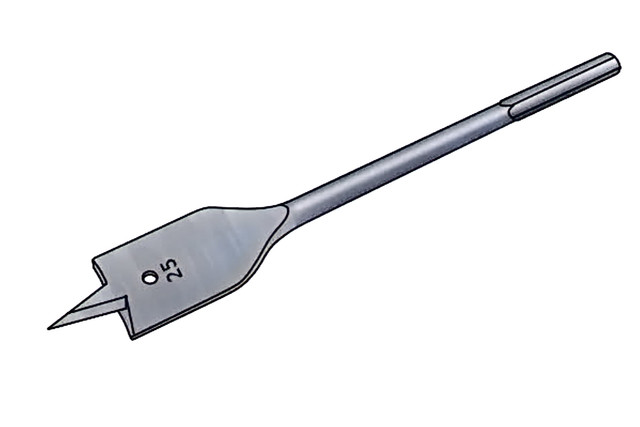

(Draw the diagram)

Flat drill: A flat drill is a type of drill bit that has a flat cutting edge at the tip instead of a pointed one. It is used for creating holes with flat-bottomed surfaces for applications where a screw or bolt head needs to sit flush with the material being drilled.

(6bii)

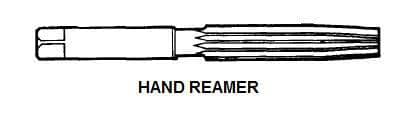

(Draw the diagram)

Hand reamer: A hand reamer is a cutting tool used for enlarging and finishing existing holes to precise dimensions. It has a straight or helical cutting edge with sharp edges that help remove material gradually. Hand reamers are often used where high precision and accuracy are needed, and they are operated manually by hand.

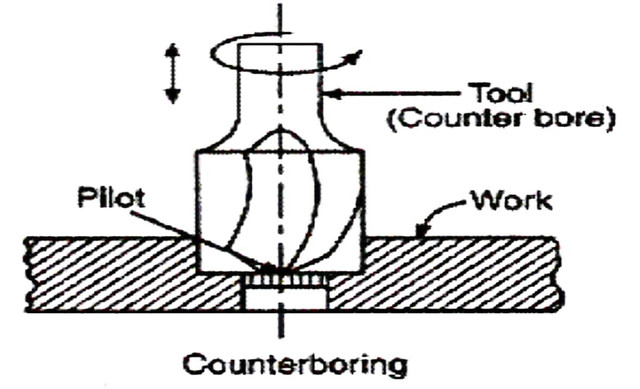

(6biii)

(Draw the diagram)

Counterboring tool: A counterboring tool is used to create a stepped recess in a material, usually to allow the head of a fastener such as a screw or bolt to sit flush with or below the material’s surface. The tool cuts a larger diameter hole at the top and a smaller diameter hole at the bottom, creating a stepped cavity.

(6c)

(i) Ductility:

-Ability of a metal to be stretched or drawn without breaking

-Measured by its percentage elongation before failure

(ii) Elasticity:

-Ability of a metal to return to its original shape after deformation

-Measured by its ability to spring back without permanent damage

(iii) Tensile strength:

-Ability of a metal to withstand pulling forces without breaking

-Measured by the amount of stress (force per unit area) it can handle before failing

==========================

COMPLETED

Leave a Reply